17.12 Uses of submerged fermentations

The fermentation processes discussed above are used in industry to produce a wide variety of fungal products. Alcohol and citric acid are the world’s most important fungal metabolites in terms of production volume. Although penicillin is still an important antibiotic, most antibiotics that we use today actually originate from bacteria (still grown in ways described above). Fungi produce some other crucial pharmaceuticals: for example, the fungal product called cyclosporine which is capable of suppressing the immune response in transplant patients to avoid organ rejection.

Another natural compound obtained from fungi that has great medical value already and seems to be increasing in clinical significance is called mevinolin. This is produced by the fungus Aspergillus terreus and is the basis of the statins, which are used to reduce cholesterol levels (risk factors in cardiovascular disease, stroke and several other widespread illnesses). Since their introduction in the late 1980s, statins have become the most widely prescribed cholesterol-lowering drugs in the world. Pfizer’s Lipitor (atorvastatin) is the most profitable drug in the history of medicine; at its peak in 2006, yearly revenue for Lipitor exceeded $US12-billion. Sales of AstraZeneca’s Crestor (rosuvastatin) reached $5.38-billion during 2009, making it one of the company’s best-selling medicines. Even though their patents recently expired, revenue for statins is still on track to reach an estimated $US 1-trillion by 2020. Statins are very big business (Demasi, 2018).

Fungi also produce compounds like the ergot alkaloids, steroid derivatives, and antitumor agents. Ergot toxins in low, controlled, concentrations are valuable drugs causing vasodilation and a decrease in blood pressure as well as contraction of smooth muscles. Although these alkaloids can be synthesised, strain improvement by mutation and selection of high-yielding strains has been so successful that fermentation remains the most cost-effective means of production.

Most of the steroids in clinical use today are modified by fungi and/or fungal enzymes during manufacture. By using fungi and their enzymes to make specific chemical transformations, compounds can be made which would be otherwise very difficult, impossible, or just too expensive to produce by direct chemical synthesis. Recently, many fungal products have been found to inhibit the growth of cancers in animal tests. Specificity and safety are the issues that presently limit the medical usefulness of most of these compounds (they may have adverse effects on healthy tissue as well as the tumour). Compounds that work by modifying the activity of the patient’s own immune system (immunomodulators), making it more active against the cancer cells, seem likely to offer the greatest value. In summary, the fungal products that contribute to our daily lives range through:

- primary metabolites, particularly fatty acids and organic acids, of which citric acid is the main one, but another example is the polyunsaturated fatty acid arachidonic acid which has useful clinical effects in lowering cholesterol and triacylglycerols in plasma, with good effects on arteriosclerosis and other cardiovascular diseases, and is added to infant formula because it is present in breast milk and is important in brain and retina development in newborn infants (Tallima & El Ridi, 2017; Das, 2018);

- secondary metabolites, most of which are used as pharmaceuticals like the antibiotics penicillin and cephalosporin, as well as cyclosporine and the statins (Rodrigues, 2016);

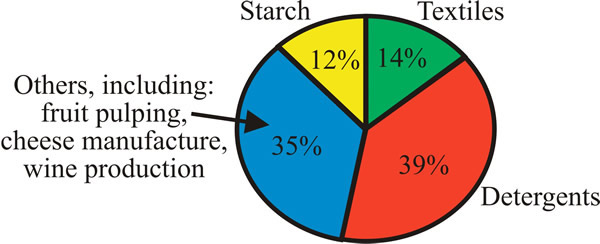

- numerous enzymes, including cellulases, amylases, lipases, proteinases, which have a tremendously diverse range of uses in industry (Fig. 27):

- textile processing: cellulolytic enzymes, particularly in denim treatment (to provide the ‘stone washed’ finish) and biofinishing of fabrics with cellulases and proteinases to remove loose fibres;

- biological detergents: which have to be active under alkaline conditions and therefore favour fungal proteinases, lipases, amylases and cellulases, also used for fabric conditioning in colour brightening (removal of broken fibres that scatter light and dull the colour) and fabric restoration;

- starch hydrolysis by amylases: for production of high fructose syrups used in confectionary manufacture;

- cheese making: fungal proteinases have been used as an alternative to bovine chymosin for many years, but increasing use is being made of bovine chymosin expressed in genetically modified yeasts and Aspergillus niger;

- brewing: fungal α-amylase, glucanases and proteinases are used to improve extraction from barley during the ‘mashing’ process prior to fermentation in beer production;

- wine and fruit juice conditioning: fungal pectinases are used to remove pectin to pulp and peel fruits and vegetables and clarify liquors;

- proteinases: are used to modify protein from a wide variety of sources, for example removal of hairs and bristles from hides during leather production;

- baking: xylanases are used to increase dough volume by making more polysaccharides available to the yeast;

- pharmaceutical production: extracted fungal enzymes can be used to modify sterols and other precursors during preparation of semisynthetic pharmaceuticals, for example 6-amino penicillanic acid (6-APA) is a semisynthetic penicillin precursor, the side chain of which can be removed by a penicillin-V acylase.

|

|---|

| Fig. 27. Main applications of fungal enzymes. |

Among the fungi that are principally used in industry for these production processes are:

- Aspergillus niger: glucoamylase, other enzymes, citric acid;

- Aspergillus oryzae: α-amylase, other enzymes;

- Trichoderma reesei: cellulase;

- Penicillium chrysogenum: penicillins;

- Cephalosporium acremonium; cephalosporins;

- Fusarium venenatum: protein food;

- Mortierella sp.: arachidonic acid.

Filamentous fungi are used for enzyme production because many strains have excellent production and secretion capacity; for example strains of Trichoderma reesei produce yields of cellulase up to 40 g l-1 (50% of which is cellobiohydrolase produced from a single copy gene). These high yields reflect the life style of filamentous fungi, specifically extracellular polymer degradation and the fact that enzyme secretion is linked to hyphal tip growth, so maximising tip growth maximises protein secretion. Indeed, genetically modified filamentous fungi offer great promise as cell factories for production of heterologous proteins because they:

- express these high production and secretion capacity, and

- can be cultivated under established fermenter conditions, and

- fungi have similar post-translational protein modification processes to mammalian systems, and

- several, if not many, fungi have ‘GRAS’ (Generally Recognised as Safe) status because of their long history in food use and/or traditional technologies (Bourdichon et al. (2012) provide an authoritative listing of microorganisms with a documented use in food).

We will deal with many of these enzyme production techniques, particularly those that involve genetic modification, in Chapter 18. In this Chapter we intend to concentrate on what might be called the traditional biotechnology industries: those in which the intact fungal organism is carrying out the industrialised process. These actually include worldwide industries with the greatest commercial values (Table 8 on the next page) (Hutkins, 2006; Montet & Ray, 2015):

- alcoholic beverage production (ales, beers, lagers, wines, and spirits),

- baking (all leavened bread),

- cheese and salami manufacture,

- production of high fructose syrup sweetening agent for the confectionary industries.

- Mushroom cultivation is the most obvious way in which we exploit fungi. In this worldwide industry about thirty species are commercially cultivated, seven being cultivated on what could be described as industrial scale.

But mushroom cultivation suits all scales from peasant farms through smallholdings and on to multi-million dollar, highly mechanised farms. However, the mushroom farming industry uses solid state fermentation processes, rather than submerged liquid cultivations, and we will deal with these towards the end of this Chapter.

Updated July, 2019